Published five years ago at my idled website Notable Discoveries. With a few updates, it is here for a change of pace after too much negative news.

Long ago mother baked regularly, but I envied our neighbours’ store-bought white bread. It had a thin soft crust and gumminess perfect for spitballs. And children in those homes did not wear pajamas sewn from flour sacks.

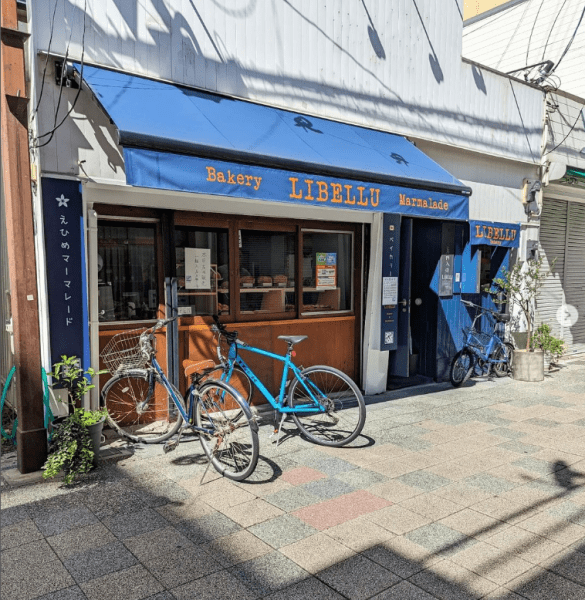

In the 1990s, the adult version of me had given up pillow-breads and discovered Vancouver’s first craft bakery. It was Ecco Il Pane (Here is the Bread), an enterprise created by Chef Chris Brown and Pamela Gaudreault. After the partners split, Ecco il Pane disappeared. Brown formed Rise Artisan Bakery and sold his goods at local markets. Then he was a co-founder of Batard Boulangerie and Café Moderne. Today, Chris is in Matsuyama, on the Japanese island of Shikokun, doing what you would expect.

In 1994, Vancouver Sun writer Mia Stainsby noted that baker Brown had done away with “sugar, oil and dairy — the bread base is flour, water, yeast and salt, knowingly kneaded by hand, not machine. Herbs, vegetables, fruit, chocolate, black mission figs, olives and other delights add real flavor.”

In 2015, Brown told Stainsby that great bread needs crazy passion. “I still get excited every time I pull a batch out. There are so many variables at play. I like the beauty of small batches; they’re gifts coming out of the oven.”

Popular success brings challenges and artisan bakers struggle to scale up production while keeping excellent quality. Using natural leaveners and ancient whole grains is a costly process. Artisan bread demands skilled hands to deal with constant variations. As sales volumes rise, bookkeepers suggest craft be sacrificed for cost efficiency. In that advice is followed, handmade breads become more like factory foods.

But, we can still find individuals producing small batches of extraordinary baked goods.

Vadim Mugerman, owner and head-baker of Bad Dog Bread is one. He and his team do their work while most of us sleep, next-door to Orto Artisan Pasta, a successful North Vancouver restaurant run by Brigitte and Steeve Raye.

Vadim Mugerman told me, “Time is the most important ingredient in good bread but it’s never listed on labels.”

Indeed, the dough Vadim started yesterday will be the bread baked tomorrow. Long, slow fermentation develops complex flavours and minimizes kneading time. Enzymes break down tangled proteins of flour and yeast actions slowly reorganize them, allowing bread with excellent gluten structure and open crumb.

Wood burning brick ovens may be treasured by romantics, but modern artisan bakers prefer well-lit, stone-deck, steam injection modules, each allowing precise control over temperature and humidity.

Bad Dog Bread proprietor Vadim Mugerman learned his trade in French, Belgian and German bakeries. He knew that while mixing, proofing and baking methods were critical, quality ingredients turned good into great. This is particularly true of whole grain flours where freshness lasts days or weeks, not months. In-house flour production solves that problem.

One technique Mugerman observed in Germany was a gentle spray of water onto bread just out of the oven. It adds shine and subtle improvements to the crust.

Breads from artisan bakeries offer better taste and nutrition than supermarket fare. Yet, premium breads are not found on most tables. Partly, this results from lack of consumer education. Clearly, potential customers resist premium prices.

Vadim says that many people have no difficulty paying $5+ dollars for a specialty coffee. He might also have mentioned $10 dollars or more for an unhealthy burger combo. He notes, “One of my multigrain loaves could feed a family of four for a day.”

In medieval times, bread was a staple for all classes, although poor people usually ate cheaper but healthier whole grain products. Wealthy folks opted for breads from refined white flours, so being rich was a disadvantage.

Bad Dog Bread began by in-house grinding of organic, grown-in-BC whole grains. Initially, space limitations and rising demand made that difficult to continue. But a move to larger premises allowed the addition of larger stone-milling equipment. Problem solved.

Bad Dog Bread uses non-hybridized heritage and ancient grains like Red Fife, Einkorn, Emmer, Spelt, Khorasan, & Rye, sourced from small BC growers. Mugerman says that flour from large scale manufacturers lacks the freshness he treasures but also includes additives he aims to avoid.

Chemicals added to wheat flour have various purposes. Some restore nutritional content lost in processing but others are for the benefit of manufacturers, not consumers. Andrew Whitley, a leading organic baker in the UK, campaigns for better quality in bread and an end to product adulteration. Whitley wrote The Shocking Truth About Bread for The Independent newspaper. He asked:

So why are calcium propionate, amylase, chlorine dioxide and L-cysteine hydrochloride now crammed into our daily bread? This is Britain’s bread: a technological marvel combining production efficiency with a compelling appeal to the lowest common denominator of taste. It is the very embodiment of the modern age…

Modernity offers many good things, but old methods are often best for food.

If you find value in posts and dialogue at IN-SIGHTS.CA, please consider financial support. It is a simple process explained HERE.

Categories: Food

Reading this and looking at the photos made me put away the store bought bread I was going to toast for breakfast, I guess now I will have eggs instead

LikeLiked by 1 person

My god, my blood sugars are rising just looking at the photos!

LikeLiked by 1 person

Interesting and a nice change of topic!

LikeLike